Unless there is a radical shake-up in the battery market, we have to keep recycling every lithium-ion battery we can. That’s because industry specialists are already predicting critical material bottlenecks in the medium term. With this in mind, we provide a lithium-ion battery recycling update regarding progress, as demand continues to ramp up.

Current Trends in Lithium-Ion Battery Recycling

Growing demand for lithium-ion batteries is putting ongoing strain on limited global resources of lithium, cobalt and nickel. This will continue unabated – in the absence of viable alternatives – as the imperative for renewable energy increases pressure.

There are only two known ways to recover these critical battery materials, at the time of writing this lithium-ion battery recycling update:

- Decomposing spent lithium-ion batteries in a furnace using pyrometallurgy, and recovering scarce metals. This method is energy-intensive.

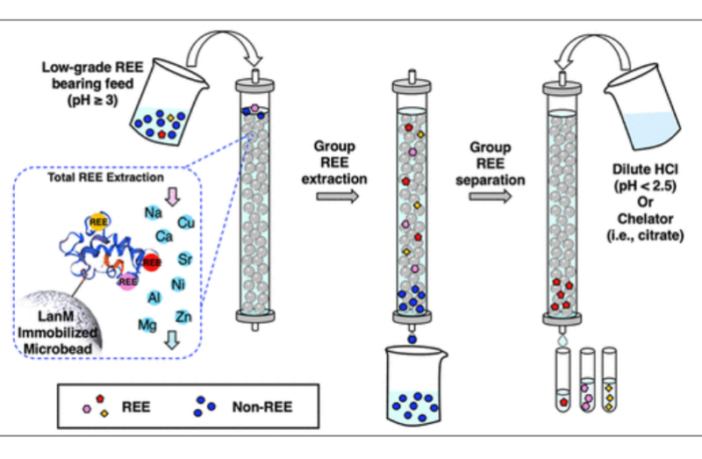

- Crushing spent batteries into fine powder, and then using hydromettalurgy to separate metals. This method is is more efficient.

Hydrometallurgy is increasingly becoming the go-to option, because it uses less energy, and puts less strain on the overall carbon footprint. Most lithium-ion battery recycling occurs in the Asia-Pacific zone, although the West is beginning to catch up.

Lithium-Cobalt Batteries Will Deliver Highest Returns

We were quite surprised by a report in ID Tech Ex to the effect that cobalt far outstrips other metals, by 90% in terms of overall recoverable value. Therefore, EE Times Europe believes lithium cobalt batteries should be a good place to start. However, these energy storage cells power consumer electronics, where the recovery rate is low.

EE Times Europe suspects this poor recycling rate is due to consumers having ‘little incentive’ to participate in the scheme. There is food for thought in that statement, because none of us is immune from global warming.

Other portable battery technologies, including nickel-manganese-cobalt oxide, and nickel-cobalt-aluminum oxide also have high-embedded content. But lithium-iron-phosphate batteries may be more suitable for second-use applications in the absence of cobalt, although they too should be ultimately recycled.

More Information

Cobalt-Free Lithium-Ion Battery on the Cards

Cobalt Mining Still a Stain on Batteries