Traditional batteries locate their terminals opposite each other, with the electrolyte between them in a rectangular configuration. This works well in a static planar arrangement, but is hardly practical in a flexible form. Fiber batteries are extruded in a longitudinal form instead. We report a wearable battery breakthrough that could lead to a successful commercial application.

Fudan Achieves Wearable Battery Breakthrough

Fiber batteries are commercially relevant, because they could be woven into soft fabrics and medical patches. Progress with practical examples has however been slow, with layer-by-layer coating only producing small batches.

Scientists at Fudan University in Shanghai, may have achieved the wearable battery breakthrough the world has been waiting for. That’s because they have produced samples of canvas and leather bags, invisibly embedded with flexible battery fibers.

This proof of concept could lead to consumers charging their phones, and watches with power from their handbags, and backpacks. A member of the Fudan team has said a bag like that could ‘wirelessly top up a mobile phone by 20% to 30% in a half hour’ (see the announcement below).

Their Inspiration Came From Creeper Plants

The Fudan team needed to find a way to use a polymer electrolyte, instead of an organic one. This was because the latter was flammable, leaked easily, and could contaminate the wearer’s skin and clothes.

But the polymer ones the team knew were jelly-like, and slipped off the fiber electrodes easily. Moreover, the lack of solid and stable contact resulted in poor energy storage, and performance.

Finally, the team gained inspiration from vines and creepers, that secrete liquids that penetrate their pores. This phenomenon ‘glues’ the creepers together, so they tangle tightly with each other.

“We designed fiber electrodes with multi-level pore structures, and devised a solution to infiltrate into the pore structure,” the corresponding author explains. A chemical reaction then created a polymer gel electrolyte, that formed a tight and stable interface with the fiber electrodes.

Their wearable fiber batteries proved robust too. They are able to resist 100 washing cycles, and 10,000 abrasion cycles which are a clothing industry standard. Their output is in the region of 128 watt-hours per kilogram. That should be more than enough to charge a drone.

More Information

Stretchable Batteries for Wearable Patches

Wearable Stretchable Batteries and Devices

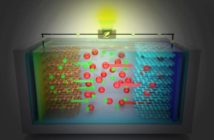

Preview Image: Impression of Woven Fiber Battery